SHRINK-FIT MACHINE & CHUCKS:

- Shrinking of Carbide and HSS tools from dia. 3 to 32 mm in tolerance h6 (up to50mm)

- Highest quality of roundness / changing repeat accuracy (< 3µm )

- Steep taper in tolerance to AT3 class with Form AD/B coolantfacility

- High clampingforce

- High temperature resistant special steel (tested more than 2000times)

- Shrink chucks are fine balanced G2.5 @ 25,000rpm

- Further balancing with tool can be done using set screws

- High quality materials used

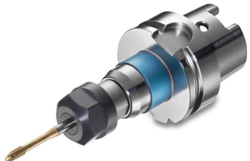

TOOL HOLDERS FOR DRILLING, TAPPING &REAMING:

- Smart solutions for high quality clamping systems in tappingapplications

- Tapping solution range from M3 –M200

- Quick and easy toolchanging

- Floating & clamping through ‘Ball catch mechanism’ to avoid wear &tear, designed for longlife

- Floating system compensate the difference between feed and pitch, increase quality of thread and toollife

- Holders are equipped with an adjustable device to increase the cutting pressure, ensuring a positive start when the tapping cycle commences

- Taps can be changed quickly without additionaltooling

- A tapping adaptor is required for each tap shanksize

- Robust design recommended for givenapplication

- Adjustable safety clutch protects against breakage of worn taps and tapbottoming

- Quick change features to suit quick change chucks with & without safetyclutch

SYNCHRO TAPPING CHUCK (SCK)

CNC TOOLHOLDERS